1L 2L 5liter PP PE HDPE Plastic Bottle Jerry Can Extrusion Blow Molding Machine Plastic Barrel Blowing Moulding Machine Price

Overview Product Description Double Station Fully Automatic Extrusion Plastic Jerrycan Blow Moulding Machine This type o

Overview

This type of machine is multi-die head full hydraulic powered automatic blow molding machine . It is suitable to produce bottles under 2.5 liter, such as source pot, peanut pot, fruit milk bottle, cosmetic bottle, 84 disinfectant, ocean ball etc.

This machine is controlled by PLC system, with characters as high stsbility, less resistance, high precision and full automaticetc. Also unattended operation can be achieved. Detailed Photos The hydraulic system adopts proportional pressure control and is equipped with well-known brand hydraulic components, which is stable and reliable.

Special Guomao hard tooth surface reducer, with the brand high torque vector inverter, stable transmission, low noise, reliable and durable.

Zhangjiagang Center Feeding Die Advantages: Make the wall thickness of the product uniform, and the color change is very convenient

The 100-point quick wall thickness control system is adopted to enable the blank to achieve effective curve control between multiple points and any point, so that the wall thickness of the product is uniform and the product quality is improved.

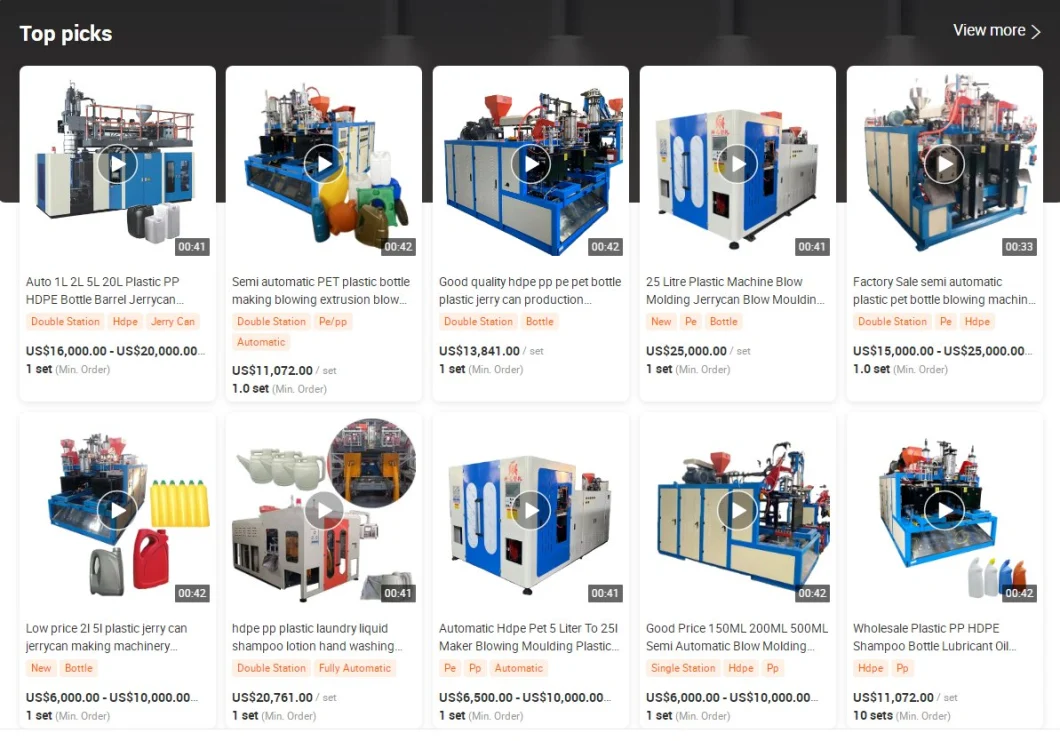

Recommend Products

After Sales ServiceWe will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians howto run the machines. 1.Competitive price2. Excellent technical support 3.Best service We offer you high quality machines withhigh quality after-service.Also we have one year warranty of the spare parts, free of charge.Packaging & Shipping CertificationsFAQQ1: Are you a trading company or a manufactory? A1: We are a manufactory, and we also own import and export license. Q2: What's your guarantee or the warranty of the quality if we buy your machines? A2: We offer you high quality machines with high quality after-service. Also we have one year warranty of the spare parts, free of charge. And customised is available. Q3: How can I install my machine when it arrives? A3: We will send our engineer to your side as soon as you get all your machines ready , for testing and guiding your technicians how to run the machines. For Extrusion Blow Molding Machine Q1: Are you a trading company or a manufacturer?A1: We own a factory ourselves, and we can assure the quality we manufactured.Q2: What's your guarantee or the warranty of the quality if we buy your machines?A2: We offer you high quality machines with high quality after-service. Also we have one year warranty of the spare parts, free of charge.Q3: How can I install my machine when it arrives?A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines.Q4: What after-sales service your company offers?A4: 1 Your inquiry related to our product & price will be replied within 72 hours.2, Well-trained & experienced staff are to answer all your inquiries in English and Chinese.3, Working time: 8:00am ~6:30pm, Monday to Saturday.4, Your business relationship with us will be confidential to any third party.5, Good after-sales service offered, please get back to us if you got any questions.Q5:Can I visit your factory and send team for learning and inspect?Q6: Yes, sure. We will do our best to teaching you how to use the machine.welcome to visit our factory! Q6: What is our advantages? A7: 1.Competitive price 2. Excellent technical support 3.Best service Q7: Where is your factory located? How can we visit there? A8: Our factory is located in Cangzhou City, Hebei Province, China.

Basic Info.

| Model NO. | XL80 |

| Certification | CE, ISO9001:2008 |

| After-sales Service | Lifetime Maintenance |

| Weight of Machine | 4.5tons |

| Screw Diameter | 80mm |

| Blowing Pressure | 0.6 Map |

| Power | 30kw |

| Max. Product Volume | 30L |

| PLC Brand | Mitsubishi |

| Modle No | XL80 |

| Transport Package | Plastic Wrap |

| Specification | 1-5L |

| Trademark | J-King |

| Origin | Cangzhou, Hebei Provice |

| HS Code | 84773000 |

| Production Capacity | 60/Hour |

Product Description

Product Description

Double Station Fully Automatic Extrusion Plastic Jerrycan Blow Moulding Machine

This type of machine is multi-die head full hydraulic powered automatic blow molding machine . It is suitable to produce bottles under 2.5 liter, such as source pot, peanut pot, fruit milk bottle, cosmetic bottle, 84 disinfectant, ocean ball etc.

Specification | 65 | 80 | ||

Machine Size | m | 4.5m*2.3m*2.4m | 4.8m*2.4m*2.5m | |

Machine Weight | Tons | 3 | 6 | |

Clamping Force | Kn | 50 | 70 | |

Template Size(W*H) | mm | 350*450mm | 400*500mm | |

Max Mold Size(W*H) | mm | 350*450mm | 400*500mm | |

Screw Diameter | mm | 65mm | 80mm | |

Screw L/D | L/D | 25∶1 | 25∶1 | |

Screw Driver Power | Kw | 11 | 15 | |

Screw Heating Power | Kw | 15 | 20 | |

Screw Screw Heating Zone | Zone | 7 | 8 | |

Double Die Center Distance | mm | 180mm | 250mm | |

Total Power | Kw | 40 | 60KW | |

Oil Pump Motor | Kw | 11 | 15 | |

Blowing Pressure | Mpa | 0.3-0.6 | 0.3-0.6 | |

Air Consumption | M3/min | 0.5 | 0.5 |

Special Guomao hard tooth surface reducer, with the brand high torque vector inverter, stable transmission, low noise, reliable and durable.

Zhangjiagang Center Feeding Die Advantages: Make the wall thickness of the product uniform, and the color change is very convenient

The 100-point quick wall thickness control system is adopted to enable the blank to achieve effective curve control between multiple points and any point, so that the wall thickness of the product is uniform and the product quality is improved.

Recommend Products

After Sales ServiceWe will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians howto run the machines. 1.Competitive price2. Excellent technical support 3.Best service We offer you high quality machines withhigh quality after-service.Also we have one year warranty of the spare parts, free of charge.Packaging & Shipping CertificationsFAQQ1: Are you a trading company or a manufactory? A1: We are a manufactory, and we also own import and export license. Q2: What's your guarantee or the warranty of the quality if we buy your machines? A2: We offer you high quality machines with high quality after-service. Also we have one year warranty of the spare parts, free of charge. And customised is available. Q3: How can I install my machine when it arrives? A3: We will send our engineer to your side as soon as you get all your machines ready , for testing and guiding your technicians how to run the machines. For Extrusion Blow Molding Machine Q1: Are you a trading company or a manufacturer?A1: We own a factory ourselves, and we can assure the quality we manufactured.Q2: What's your guarantee or the warranty of the quality if we buy your machines?A2: We offer you high quality machines with high quality after-service. Also we have one year warranty of the spare parts, free of charge.Q3: How can I install my machine when it arrives?A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines.Q4: What after-sales service your company offers?A4: 1 Your inquiry related to our product & price will be replied within 72 hours.2, Well-trained & experienced staff are to answer all your inquiries in English and Chinese.3, Working time: 8:00am ~6:30pm, Monday to Saturday.4, Your business relationship with us will be confidential to any third party.5, Good after-sales service offered, please get back to us if you got any questions.Q5:Can I visit your factory and send team for learning and inspect?Q6: Yes, sure. We will do our best to teaching you how to use the machine.welcome to visit our factory! Q6: What is our advantages? A7: 1.Competitive price 2. Excellent technical support 3.Best service Q7: Where is your factory located? How can we visit there? A8: Our factory is located in Cangzhou City, Hebei Province, China.

Send to us