Package Size 3850.00cm * 2300.00cm * 2000.00cm Package Gross Weight 4200.000kg Pet Bottle Blow Molding Machine for Water Bottle and Beverage BottleJS-4000 bottle blow molding machine is one specialty

Machine specification: Machine Features: 1.Low labor and energy cost, high efficiency and profit, with automatic bottle embryo delivery process.2.The blow molding machine has automatic alarm,

Package Size 4300.00cm * 2200.00cm * 2200.00cm Package Gross Weight 6500.000kg Full Servo High Speed Automatic Pet Bottle Blow Molding Machine 1.Pet Plastic Type And Yes Automatic Blow Molding Machine

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to

5L Pet Plastic Jar/Barrel Width Mouth Neck Edible Oil bottle Full Automatic Blow blowing Molding making MachineYCQ-5L-2E Technical parameter Features A. Stable performance with advanced PLC. B.

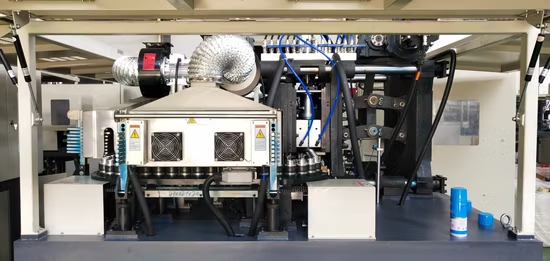

1. About one step injection stretch blow molding machine (ISBM)? --One step injection stretch blow molding machine also known as single stage blow molding machine.--It integrates the functionality of

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to

welcome to add me for further communication. Automatic PET Bottle Blow Molding Machine A. Product Description: Model :ESA-4-2000 (4 cavity)Production capacity :4000BPHApplication range : 200ml to

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to

Overview Package Size 4500.00cm * 2200.00cm * 2200.00cm Package Gross Weight 6000.000kg 9800bph High Speed Full Automatic Plastic Pet Drinking Water Juice Carbonated Drink 200ml 300ml 500ml 1L Small

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to